-

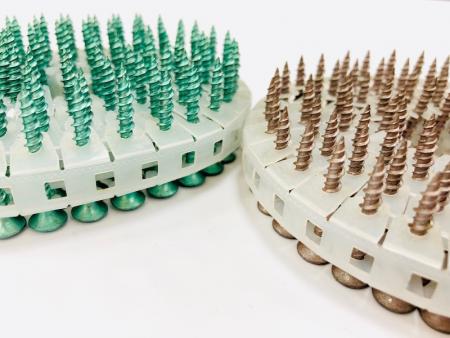

Coating Screws

There are many finishes or coating applied to fasteners; some of them can protect fasteners from corrosion, and some others are just for decorative uses. Any types of screws can be coated.

-

Indented Hex Washer Head Screw

CA009-150428-1

Process: Using multi blow header to make the head and then threading before passivation. At last surface coating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Across the flat and corner of the hex, Washer diameter, Washer height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Flat tail length, Flat tail diameter Nylok Inspection Nylok Coating Report Offered

-

Pan Head Phillips Coarse Pointed Screw

CA009-150614-1

Process: Using multi blow header to make the head and then threading before passivation. Zinc plating after heat treating. The last step being screw and washer assembly All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Phillips rec depth, Washer diameter, Washer height, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Coat inspection Inspection Reports Offered

-

Chamfered Hex Washer Head Screw

CE005-150301-1

Process: Using multi blow header to make the head and then threading before passivation. At last surface coating after heat treating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Across the flat and corner of the hex, Head height, Slot width, Slot depth, Number of serration, Ring gage GO/NO GO, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Chamfer length, Coat inspection Coat Report Offered

-

Chamfered Hex Washer Head Machine Thread

CM006-110711-1

Process: Using multi blow header to make the head and then rolling before acid washing and heat treating. At last spray painting on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Across the flat and corner of the hex, Head height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch Nylok Inspection Report Offered

-

Indented Hex Round Washer Bolt

CM006-140821-1

Process: Using multi blow header to make the head and then threading before passivation. All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection Passivation Report Offered

-

Chamfered Hex Washer Head Drilling Tail

CM006-150318-1

Process: Using multi blow header to make the head and then rolling before acid washing and heat treating. At last spray painting on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Across the flat and corner of the hex, Washer diameter, Washer height, Total head height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Coat inspection Coat Inspection Report Offered

-

Internal Hex Head Screw

CM006-150412-1

Process: Using multi blow header to make the head and then threading before passivation. Trivalent chromium zinc plating after heat treating. Coating being the last step All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Hex depth, Hex plug gauge, Minor diameter, Thread angle, Pitch, Coat inspection, Nylok inspection Coating Reports Offered Nylok Reports Offered

-

Button Head Internal Hex Rec

CM006-150412-2

Process: Using multi blow header to make the head and then threading before passivation, then assembling the screw and washer. At last surface coating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Hex depth, Hex plug gauge, Washer diameter, Washer height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Ring gage GO /NO GO Nylok Inspection Nylok Coating Reports Offered

-

Internal Hex Head Screw

CM006-150412-3

Process: Using multi blow header to make the head and then threading before passivation. At last thread nylok coating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Hex depth, Hex, Pin point diameter, Hex plug gauge, Grip gaging body diameter, Pointed thread length, Outside diameter of pointed thread, Minor diameter, Thread angle, Pitch Nylok Inspection Nylok Coating Reports Offered

-

Stainless Button Head Screw

CM006-150717-1

Process: Using multi blow header to make the head and then threading before passivation, then surface coating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Hex rec depth, Hex plug gauge, Length, Major diameter, Minor diameter, Thread angle, Pitch , Coat inspection, Ring gage GO/ NO GO

-

Pan Head Phillips Machine Thread Screw

CM006-151104-1

Process: Using multi blow header to make the head and then threading before passivation. Plating being the last step All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Phillips depth, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Ring gage GO /NO GO, Plating inspection Plating Reports Offered

-

Flat Machine Thread Drilling Screw

CM008-150812-1

Process: Using multi blow header to make the head and then threading before passivation. Plating and acid washing after heat treating. The last step being beeswaxing All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Square depth, Square plug gauge, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Drilling tail diameter, Drilling tail length, Plating inspection Plating Reports Offered

-

Flat Head #1 Square

CM008-151131-1

Process: Using multi blow header to make the head and then threading before passivation. Acid washing after heat treating. At last plating and beeswaxing All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Square depth, Square plug gauge, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Drilling tail diameter, Drilling tail length, Plating inspection Plating Reports Offered

-

Flat Head Phillips Coarse Pointed Tail

CP007-100215-1

Process: Using multi blow header to make the head and then rolling before acid washing. At last spray painting on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Head diameter, Head height, Flat head angle, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Flat Head Phillips Coarse Pointed Tail

CP007-100715-1

Process: Using multi blow header to make the head and then threading before passivation. Yellow zinc plating after heat treating. At last spray paint on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Head diameter, Head height, Flat head angle, Total length, Major diameter, Minor diameter, Pitch, Thread angle, Paint surface inspection

-

Flat Head Phillips Coarse Pointed Tail Screw

CP007-100807-1

Process: Using multi blow header to make the head and then threading before passivation. Zinc yellow after heat treating. At last spray paint on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Head diameter, Head height, Flat head angle, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Pan Head Phillips Drilling Tail

CP007-100809-1

Process: Using multi blow header to make the head and then rolling before acid washing and heat treating. At last spray painting on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Head diameter, Head height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Flat Head Phillips Coarse Pointed Tail Screw

CP007-101109-1

Process: Using multi blow header to make the head and then threading before passivation and heat treating. At last spray paint on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Screw Measurement Points: Head diameter, Head height, Thread length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Pan Head Phillips Slot

CP007-110719-1

Process: Using multi blow header to make the head and then threading before passivation. Nickel plating at last All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Phillips depth, Slot depth, Slot width, Phillips plug gauge, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Flat Head Phillips Coarse Pointed Tail

CP007-111117-1

Process: Using multi blow header to make the head and then threading before passivation. Yellow zinc plating after heat treating. At last spray paint on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Flat head angle, Total length, Phillips plug gauge, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Half Round Head Phillips Tapping Screw

CP007-130427-1

Process: Using multi blow header to make the head and then threading before passivation. Zinc plating after heat treating. At last spray paint on the head part All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Flat head angle, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Flat Head Tapping

CP007-140519-1

Process: Using multi blow header to make the head and then threading before passivation. Head Spray Paitning at last All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, 6-lobe depth, 6-lobe plug gauge, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Paint surface inspection

-

Flat Head Phillips Coarse Pointed Tail

CP007-150725-1

Process: Using multi blow header to make the head and then threading before passivation. Plating after heat treating All the items are inspected during the process and before shipping, complying with ISO Working Instruction Inspection Tools: Calipers, Protrusion-height gage, Micrometer, 2.5D and 2D projector Measurement Points: Head diameter, Head height, Phillips rec depth, Phillips plug gauge, Total length, Major diameter, Minor diameter, Thread angle, Pitch, Plating inspection, AASS AASS Reports Offered